Products

Our Newsletter

Self Tensioning Drums

Self Tensioning Drums![]() Introduction

Introduction

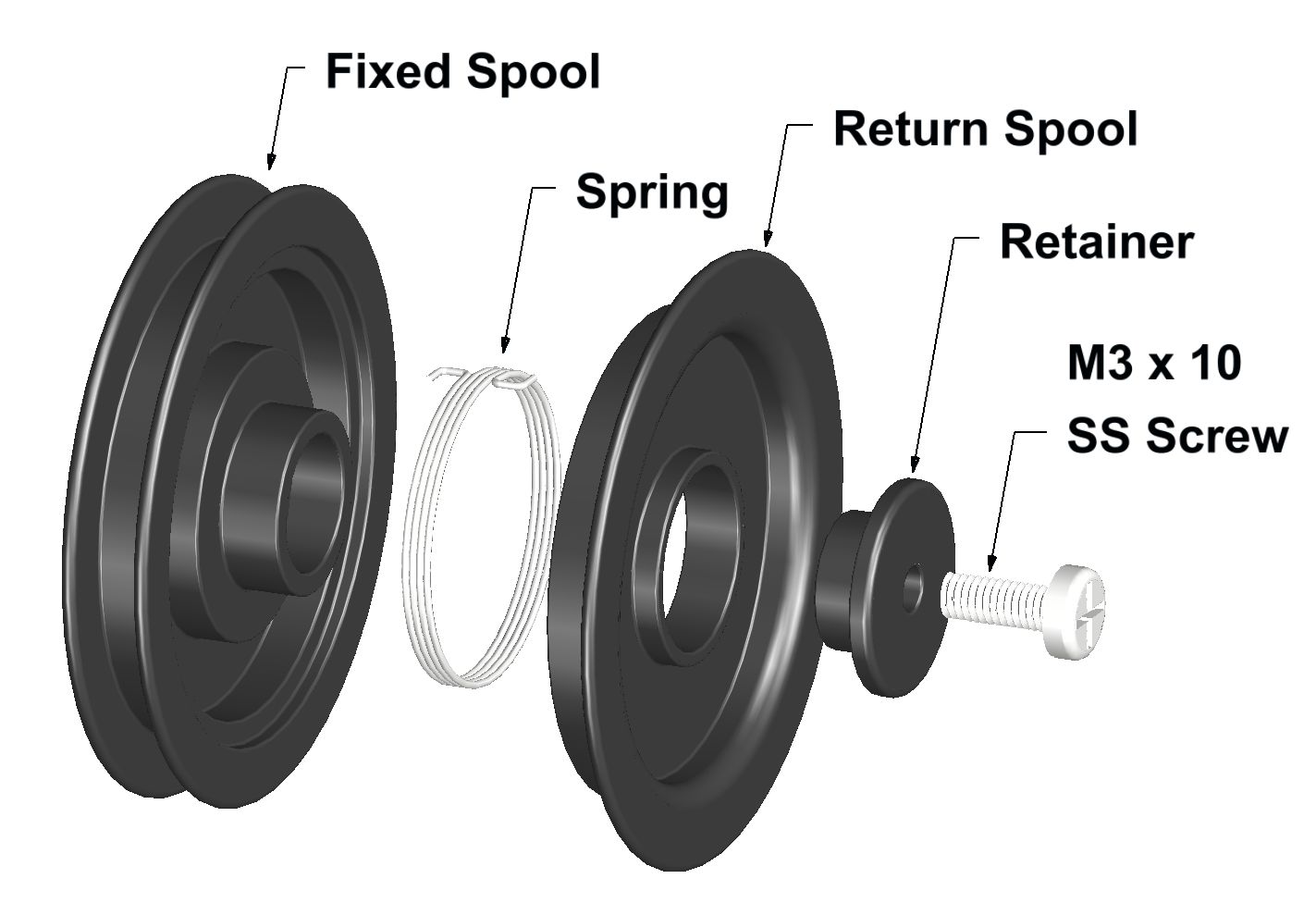

The RMG self tensioning drums allow for the elimination of tensioning devices in the sheeting system such as shock cord, rubber band material, hat elastic, springs etc. The spring loaded return spool in these drums takes up any slack and maintains a positive tension in the sheeting system.

![]() Drum Direction

Drum Direction

26 mm and 32 mm spool type ST Drums are available in Left and Right hand versions. If the winch drum turns clockwise (viewed from top of drum) to sheet OUT, the Right hand ST drum should be used. When the winch turns anticlockwise to sheet OUT the Left hand ST drums is used.

The 45zs4st is right hand only.

![]() How To Use

How To Use

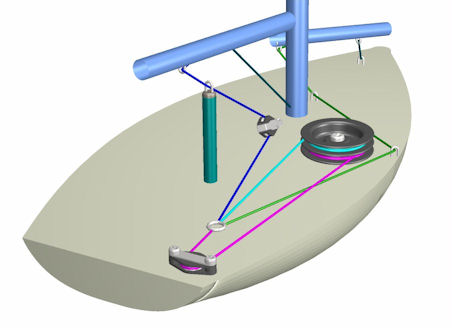

At right is an example layout for a right hand ST drum. Note that the load bearing line (pink) comes from the bottom spool and the return line (light blue) goes back to the top spool. This is essential for any ST drum.

The 32mm and 26mm spool type self-tensioning drums has only a small difference in travel between the fixed spool and the return spool so the majority of the spring travel can be used to generate tension. Ensure that there is always at least a small amount of travel left in the spring at any position from full in to full out.

For the 45zs3st there is a difference of about 3/4 of a turn difference between the travel of the spiral and the return spool. The point of maximum differential occurs about 100 mm travel distance out from the spiral fully loaded (close hauled) position. So when the drum is at close hauled or at full out, the return spool should have about one full turn left in the spring. If less than 3/4 for 45zs4st is left in the spring, then the spring will bind and damage is possible.

![]() Loading

Loading

Start by loading the bottom (load) spool with enough line plus a couple of turns for the required travel and with jib and main lines connected, set the booms to close hauled. Then attach the return line to the top spool. Put a couple of turns on that spool then feed it through the splitter ring as per the above drawing. Once the return line is fed through the splitter, pull on the line to tension the return spool spring. Take it to the point where there’s no more travel in the spring then back off about ¼ turn or so then tie the line off at the splitter.

![]() Main Points

Main Points

- The spring must not become bound at any position in the normal travel of the system. There must always be some spring travel remaining.

- The fixed (bottom) spool must be used to pull the sails in.

- The return (top) spool must not be used to pull the sails in.

- The correct direction of travel must be used (see Drum Direction above).

- Recommended maximum line size is 36kg (80lb) Spektra.

- Spool type st drums (26 & 32mm) should have about 1/4 turn free travel left in the return spool in all travel positions.

- Spiral type st drums (45mm) should have about 1 full turn of return spool travel left when at close hauled.

- At least 1 complete turn of line should remain on each spool at any time.

- When deck mounted and if sailing in salt water, rinse the drum out with fresh water at the end of the day to prevent salt crystallization. This is the best lubrication for these drums.