Products

Our Newsletter

How To Program a SmartWinch E Series Revision 1

The programing differences:

- Revision 1 uses ground pin for Setup 1 and Setup 2.

- Revision 1 uses signal pin for Setup 3.

- Setup 2 and 3 are combined in revision 2.

- Signal pin is used for all adjustments in revision 2.

- Ramp Rate is not available in revision 1.

For description of the adjustable features click here.

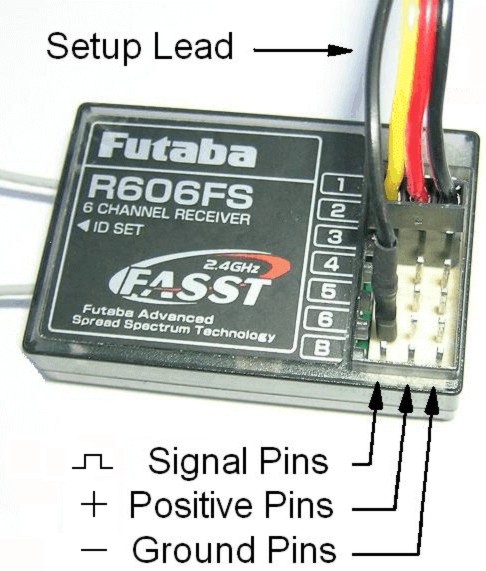

Adjustments are made by placing the winch in setup mode. Setup is entered by connecting the Setup Lead to a spare ground pin for Setup 1 and Setup 2 or signal pin for Setup 3 into the Rx. The Setup Lead is the single wire with a small connector.

The picture shows a multi channel Rx. If using a two channel Rx the rudder servo lead will need to be removed to access a signal pin. The Setup Lead is shown connected to a signal pin. For normal operation, leave the Setup Lead connected to any spare center pin (positive). Allowing the lead to dangle free in the bilge is a recipe for corrosion and Setup Lead failure.

Ground pins are the outside row and are used by the black (or brown) wire of the servo lead.

Positive pins are the center row (red wire).

Signal pins are the inside row (white or yellow).

The inside row pin of the Rx battery connector is not a signal pin and can not be used for Setup.

If the Setup Lead is connected to a signal or ground pin when the winch is turned on, there will be a rapid repeated beep. Reposition it to a center pin for normal operation.

Setup is not essential to operate the SmartWinch. Travel can be set using a Tx EPA if available. However this is a powerful servo which can do damage if overrun occurs. Setup 1 is a simple and safe way to adjust travel.

Setup does not correct faults. If the winch has a problem Setup will not solve it. Settings can be overwritten thousands of times so you can experiment with different settings as much as you like.

![]() Setup Procedure 1 Tx End Point Limits and Travel

Setup Procedure 1 Tx End Point Limits and Travel

- Remove drum if first time for Setup 1 or after reset done in Setup 2. Turn radio and winch on and check that the winch is responding to the Tx.

- Place Tx stick at full in position and adjust trim all the way in the same direction as the stick.

- Connect Setup Lead to Rx ground pin and wait for a 1 second long sound signal.

About 2 seconds after connection there will be a ring tone like sound signal.

- Move Tx stick to full out and wait for another 1 second long sound signal.

The 2nd sound signal indicates that the Tx end points have been read and saved.

- Move Tx Stick back to full in.

If not already there, the winch will drive to its zero point then sound a third sound signal.

- Fit drum and manually adjust the lines to set the main boom at full in. Ensure Tx stick remains at close hauled for this step.

- Using the Tx stick, drive the winch out until the booms are at the desired full out position.

The winch will run at a lower speed at this time. Take care not to go too far out as travel is set to maximum at this time.

- With the winch still at the new full out position, remove Setup Lead from Rx.

The SmartWinch will automatically restart with the new settings.

This completes Setup 1. If no more adjustment is required then push the Setup Lead onto a spare centre pin for storage during normal winch use.

![]() Setup Procedure 2 Battery Monitoring

Setup Procedure 2 Battery Monitoring

Note: Setup 1 must have been run previously but does not need to be done each time Setup 2 is run.

- Turn Tx and winch on and ensure winch is responding to Tx.

- Place Tx stick at full in to turn Battery Monitoring on OR

Place Tx stick at full out to turn Battery Monitoring off.

- Push Setup Lead onto Rx ground pin and wait for a 1 second long sound signal.

About 2 seconds after connection there will be a ring tone like sound signal.

- Remove the Setup Lead from the Rx. Do not move the Tx stick before doing so.

1, 2, 3 or 4 beeps will sound indicating battery monitoring level set.

The winch will then restart itself with the new settings.

This completes Setup 2. If no more adjustment is required then push the Setup Lead onto a spare centre pin for storage during normal winch use.

![]() Setup Procedure 3 Auxiliary Settings

Setup Procedure 3 Auxiliary Settings

Note: Setup 1 must have been run previously but does not need to be done each time Setup 3 is run.

- Turn Tx and winch on and ensure winch is responding to Tx.

- Place Tx stick at desired position.

For SLT & ISDB, drive the SmartWinch (via Tx stick) to full in for minimum, full out for maximum or any intermediate position as desired.

For LBS, place boom at desired shutdown position. The range available is half to maximum turns. A position of less than half will result in half turns position. For Reset to default, stick position is not important.

- Push the Setup Lead onto a spare RX signal pin.

About 2 seconds after connection a there will be one beep per second up to 10 beeps.

- Remove the Setup Lead immediately the required number of beeps has sounded. See table 1 below.

If you accidentally pulled the lead out at the wrong number of beeps then just turn the winch off now and the previous setting will not change.

- Hold the Setup Lead onto a signal pin until the startup signal then remove the Setup Lead from the Rx. There is no need to push it completely onto the pin for this step.

The startup signal indicates that the SmartWinch has restarted with the new setting.

This completes Setup 2. If no more Setup is required then push the Setup Lead onto a spare centre pin for storage during normal winch use.

Setup 3 Beeps Count Table 1

| Beeps | Setting |

| 1 | Single ended Scaled Linear Travel (SLT) |

| 2 | Double ended Scaled Linear Travel (SLT) |

| 3 | Low Battery Shutdown Position (LBS) |

| 4 | Deadband (DB) |

| 10 | Reset All settings to default. Drum must be removed first. |